SSZTCH8 july 2015 DRV8840

Motor regeneration is a common problem that occurs in motor-drive systems. Many designers have to select a motor supply voltage (VM) rating of twice the nominal level, which adds to the system cost. Fortunately, if you can first understand the pumping details, you can understand the necessary VM margin. In the first post in this series on frequently asked questions, Nicholas Oborny provided advice on how to read a motor driver datasheet. Today, I’ll continue the conversation by introducing a method for estimating the pumping level.

VM Pumping Waveform

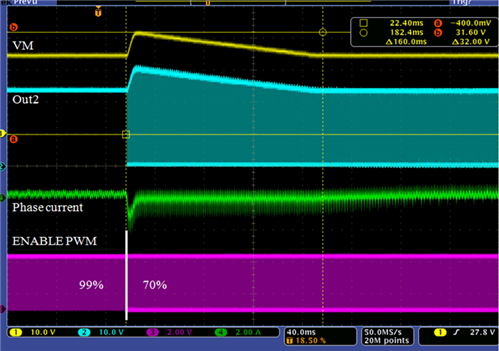

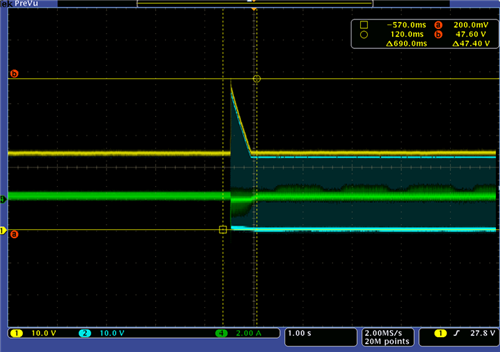

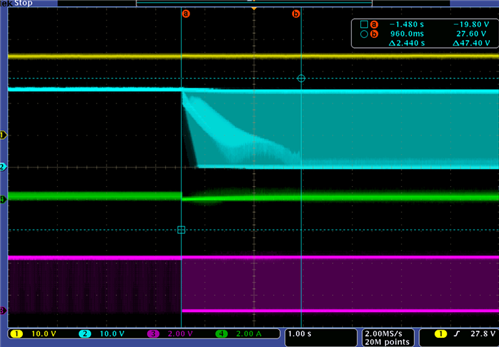

Figure 1 shows a typical VM pumping waveform caused by regeneration during a deceleration process. When the input PWM (pulse-width modulation) duty changed from 99% to 70%, the VM voltage was pumping from 24V to 32V. (Tested on TI motor driver device DRV8840, a 5A Brushed DC Motor Driver.)

Figure 1 Regeneration and VM Pumping

Figure 1 Regeneration and VM PumpingPumping Mechanism

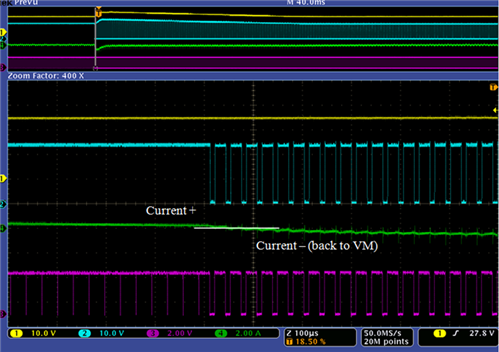

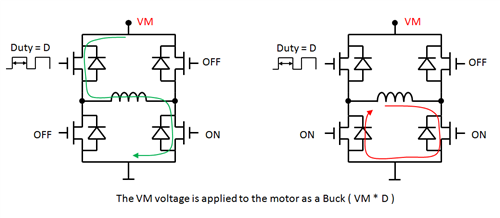

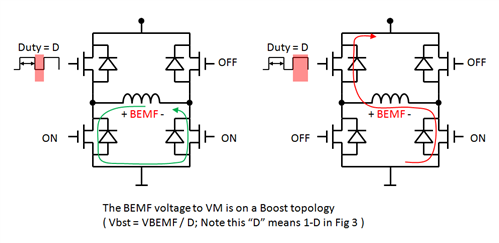

We need some DC/DC power management background here to understand the pumping mechanism. So, let’s look at how a typical buck-boost circuit works; see Figure 2. What’s interesting is that during PWM, driving a motor with an H bridge, you have the buck and boost process together. As shown in Figure 3, during the PWM’s driving time, it’s a typical buck circuit. In Figure 4, the back electromotive force (EMF) is acting as the boost source during the PWM’s off time.

Figure 2 Buck and Boost

Circuits

Figure 2 Buck and Boost

Circuits Figure 3 Buck Topology

Figure 3 Buck Topology Figure 4 Boost Topology

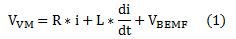

Figure 4 Boost TopologyThe running model of the brushed DC motor can be shown as equation Equation 1.

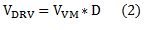

In normal driving conditions with a PWM duty cycle = D, the motor will run at a speed driven by a voltage VDRV as shown in equation Equation 2.

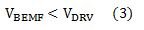

Based on Equation 1, we should have

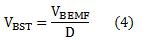

The boost effect will give the VBST as

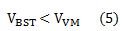

From Equation 2, Equation 3, Equation 4, we can get

So, there is no VM pumping in a normal running condition.

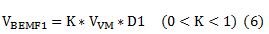

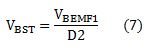

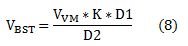

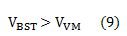

When the PWM duty cycle is reduced from D1 to D2, just before the reducing point, we have

Just after the reducing of duty, the speed of the motor can’t change suddenly, so the VBST is based on the new duty cycle D2 as

From Equation 6, Equation 7, we can get

When K*D1/D2 > 1, we get

VBST will be higher than VVM and causing a pumping effect. Assuming that K is close to 1, any time you reduce the duty cycle with D2 < D1, VM pumping will occur. For example, if you go from 100% to 50%, VBST = 2*VM. And if you go from 90% to 30%, there will be 3x higher pumping voltage seen from VM.

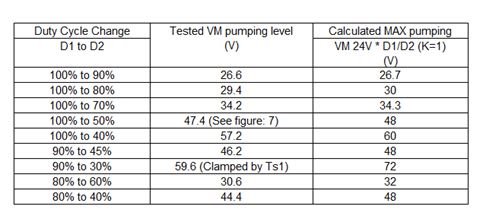

Pumping Tests

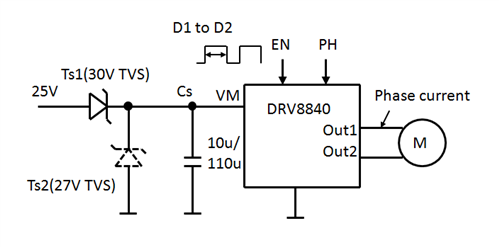

In practice, VM pumping may not be seen as high as estimated by the above Equation 8, because the power supply and VM caps will have sinking ability which helps to reduce the pumping level. To verify the estimating method, we add a diode Ts1 from the power supply to the VM, as shown in Figure 5, trying to get the pure pumping effect without power supply sinking.

Figure 5 Pumping Voltage Tests

Figure 5 Pumping Voltage TestsFigure 6 and Figure 7 show the test results. (Note: Some pumping voltage is over the VM spec of the DRV8840 datasheet; this is for test only. The device is never recommended to be used in over-spec conditions.)

Figure 6 Tested Result and Calculated

Result

Figure 6 Tested Result and Calculated

Result Figure 7 Bar Plot of Results

Figure 7 Bar Plot of Results Figure 8 VM Pumping When PWM Reduces

from 100% to 50% (with Ts1 on Figure 5)

Figure 8 VM Pumping When PWM Reduces

from 100% to 50% (with Ts1 on Figure 5)Reducing Voltage Pumping

There are two ways to control VM pumping:

- Use fast decay. With DRV8840 in fast decay mode, the boost topology shown in Figure 4 is no longer present. The back EMF will always be

less than the VM voltage, and VM pumping will not occur at all. It will take a longer time to achieve the targeted speed, as shown in Figure 9.

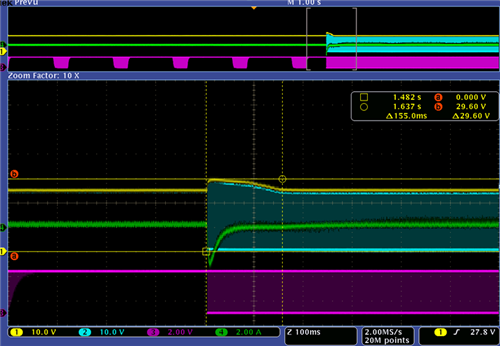

Figure 9 No VM Pumping with Fast Decay

Figure 9 No VM Pumping with Fast Decay - Use a transient voltage suppressor (TVS) to clamp the VM pumping. If you choose the TVS with clamping voltage a little higher than the nominal VM rating and place it as Ts2, shown in Figure 5, it will clamp the VM pumping (see Figure 10). I used a 27V TVS and the VM pumping was effectively clamped at 29.6V. The TVS also functioned as dynamic braking so that

the motor has a quick deceleration process.

Figure 10 Figure 9

Figure 10 Figure 9

Summary

In a motor deceleration process, VM pumping actually shows the kinetic energy transferring into electrical energy. Consider the below factors:

- The boost topology is a key factor as to why the back EMF can force current back to the VM supply, even when VBEMF < VVM.Fast decay will not cause VM pumping during the deceleration section, but it will take a longer time for the motor to slow down.

- A TVS clamping method or other dynamic braking method can be a good way to reduce VM pumping while keeping the fast deceleration rate.

Additional Resources

- Read more blog posts in this series on frequently asked questions from the forum.

- Download the DRV8840 datasheet.