SLVK099B March 2022 – September 2023 TPS7H5001-SP , TPS7H5002-SP , TPS7H5003-SP , TPS7H5004-SP

PRODUCTION DATA

- 1

- Abstract

- Trademarks

- 1 Introduction

- 2 Single-Event Effects (SEE)

- 3 Device and Test Board Information

- 4 Irradiation Facility and Setup

- 5 Depth, Range, and LETEFF Calculation

- 6 Test Setup and Procedures

- 7 Destructive Single-Event Effects (DSEE)

- 8 Single-Event Transients (SET)

- 9 Event Rate Calculations

- 10Summary

- A Total Ionizing Dose from SEE Experiments

- B References

- C Revision History

5 Depth, Range, and LETEFF Calculation

![TPS7H5001-SP Generalized Cross-Section of

the LBC7 Technology BEOL Stack on the TPS7H500x-SP [Left] and SEUSS 2020

Application Used to Determine Key Ion Parameters [Right] GUID-20220201-SS0I-LS5M-M2L0-676MV66GSKMM-low.jpg](/ods/images/SLVK099B/GUID-20220201-SS0I-LS5M-M2L0-676MV66GSKMM-low.jpg) Figure 5-1 Generalized Cross-Section of

the LBC7 Technology BEOL Stack on the TPS7H500x-SP [Left] and SEUSS 2020

Application Used to Determine Key Ion Parameters [Right]

Figure 5-1 Generalized Cross-Section of

the LBC7 Technology BEOL Stack on the TPS7H500x-SP [Left] and SEUSS 2020

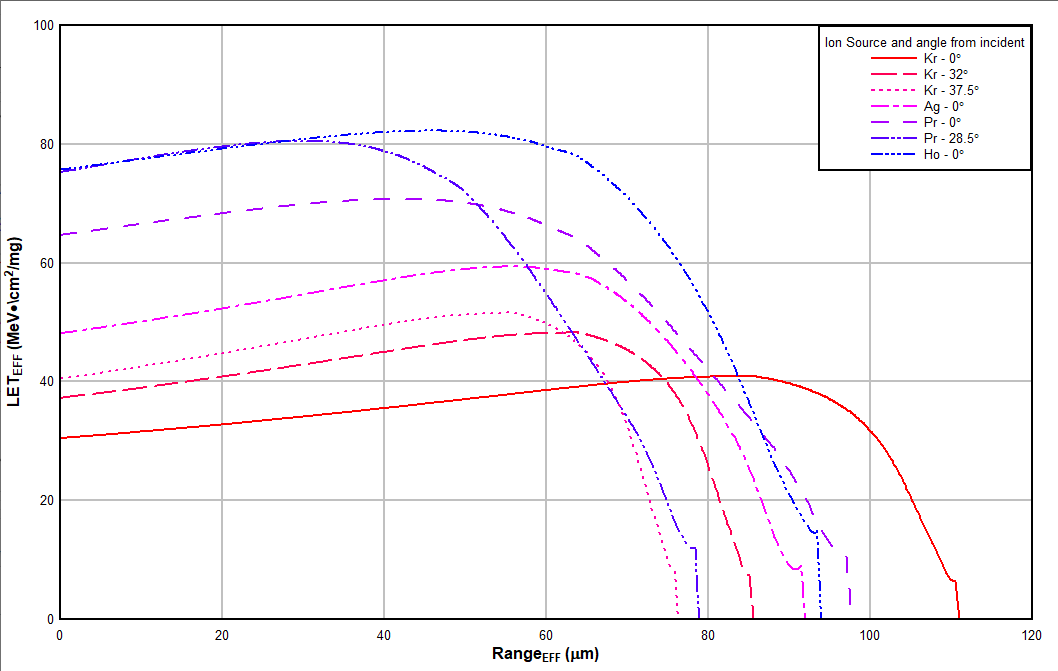

Application Used to Determine Key Ion Parameters [Right]The TPS7H500x-SP is fabricated in the TI Linear BiCMOS 250-nm process with a back-end-of-line (BEOL) stack consisting of 4 levels of standard thickness aluminum. The total stack height from the surface of the passivation to the silicon surface is 11.44 μm based on nominal layer thickness as shown in Figure 5-1. Accounting for energy loss through the 1-mil thick Aramica beam port window, the 40-mm air gap, and the BEOL stack over the TPS7H500x-SP, the effective LET (LETEFF) at the surface of the silicon substrate, the depth, and the ion range was determined with the SEUSS 2020 Software (provided by the Texas A&M Cyclotron Institute and based on the latest SRIM-2013 models [7]). Table 5-1 shows the results . The LETEFF vs range for the used heavy-ion are shown inFigure 5-2. The stack was modeled as a homogeneous layer of silicon dioxide (valid since SiO2 and aluminum density are similar).

| Ion Type | Beam Energy (MeV/nucleon) | Angle of Incidence | Range in Silicon (μm) | LETEFF (MeV·cm2/mg) |

|---|---|---|---|---|

| 84Kr | 15 | 0 | 111 | 30.5 |

| 15 | 32 | 85.1 | 37.3 | |

| 15 | 37.5 | 76 | 40.6 | |

| 109Ag | 15 | 0 | 92 | 48.1 |

| 141Pr | 15 | 0 | 97.6 | 65 |

| 15 | 28.5 | 79 | 75 | |

| 165Ho | 15 | 0 | 94 | 75 |

Figure 5-2 LETEFF vs Range for

Used Heavy Ions During the SEE Test Campaign

Figure 5-2 LETEFF vs Range for

Used Heavy Ions During the SEE Test Campaign