SLVK086A january 2022 – may 2023 TPS7H4003-SEP

PRODUCTION DATA

- 1

- Single-Event Effects Test Report of the TPS7H4003-SEP Synchronous Step-Down Converter

- Trademarks

- 1 Introduction

- 2 Single-Event Effects (SEE)

- 3 Device and Test Board Information

- 4 Irradiation Facility and Setup

- 5 Depth, Range, and LETEFF Calculation

- 6 Test Setup and Procedures

- 7 Destructive Single-Event Effects (DSEE)

- 8 Single-Event Transients (SET)

- 9 Event Rate Calculations

- 10Summary

- A Appendix: Total Ionizing Dose From SEE Experiments

- B Appendix: References

- C Revision History

5 Depth, Range, and LETEFF Calculation

![TPS7H4003-SEP Generalized Cross-Section of the LBC8 Technology BEOL Stack on the TPS7H4003-SEP [Left] and SEUSS 2020 Application Used to Determine Key Ion Parameters [Right] GUID-20211214-SS0I-2HKG-N9RJ-HTBVHPD4GF6B-low.jpg](/ods/images/SLVK086A/GUID-20211214-SS0I-2HKG-N9RJ-HTBVHPD4GF6B-low.jpg) Figure 5-1 Generalized Cross-Section of the LBC8 Technology BEOL Stack on the TPS7H4003-SEP [Left] and SEUSS 2020 Application Used to Determine Key Ion Parameters [Right]

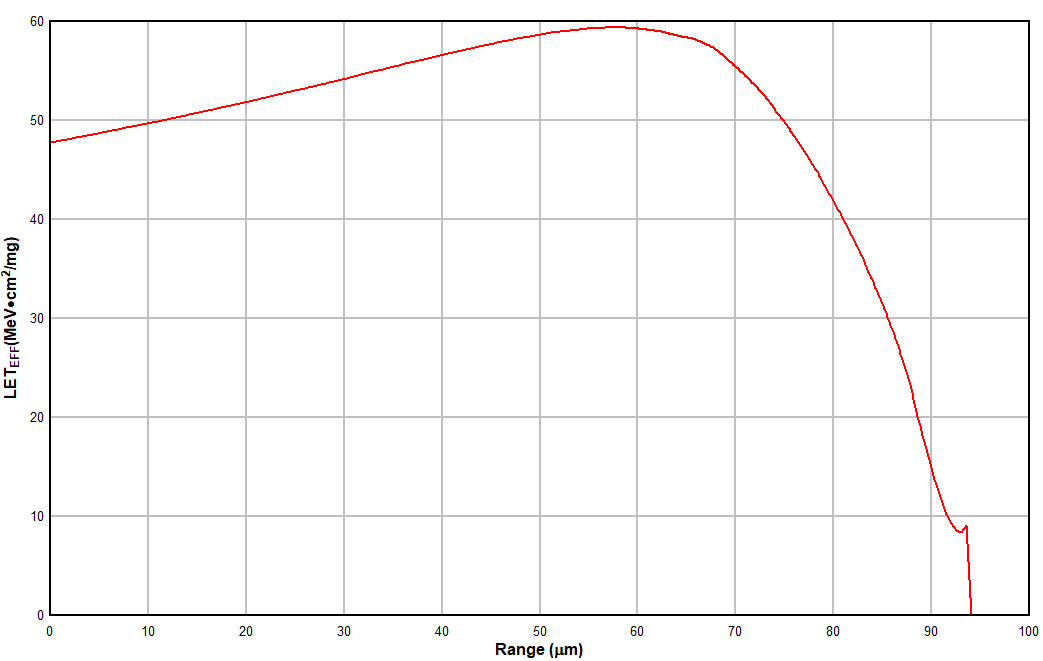

Figure 5-1 Generalized Cross-Section of the LBC8 Technology BEOL Stack on the TPS7H4003-SEP [Left] and SEUSS 2020 Application Used to Determine Key Ion Parameters [Right]The TPS7H4003-SEP is fabricated in the TI Linear BiCMOS 250-nm process with a back-end-of-line (BEOL) stack consisting of 5 levels of standard thickness aluminum metal on a 0.6-μm pitch. The total stack height from the surface of the passivation to the silicon surface is 13.54 μm based on nominal layer thickness as shown in Figure 5-1. Accounting for energy loss through the 1-mil thick Aramica beam port window, the 40-mm air gap, and the BEOL stack over the TPS7H4003-SEP, the effective LET (LETEFF) at the surface of the silicon substrate, the depth, and the ion range was determined with the SEUSS 2020 Software (provided by the Texas A&M Cyclotron Institute and based on the latest SRIM-2013 [7] models). The results are shown in Table 5-1. The LETEFF vs range for the 109Ag heavy-ion is shown on Figure 5-2. The stack was modeled as a homogeneous layer of silicon dioxide (valid since SiO2 and aluminum density are similar).

| ION TYPE | DEGRADER ANGLE | RANGE IN SILICON | LETEFF (MeV·cm2/mg) |

|---|---|---|---|

| 109Ag | 0 | 91.6 | 48.2 |

Figure 5-2 LETEFF vs Range for

109Ag at the Conditions Used for the SEE Test Campaign

Figure 5-2 LETEFF vs Range for

109Ag at the Conditions Used for the SEE Test Campaign